Client Case Studies

We partner with every client to ensure customized solutions that not only reach goals but provide a competitive advantage. Explore our Case Studies to see real-world examples of companies reaching the next level.

Featured Case Studies

Super Thin Saws Sharpens Their Current Condition And Plans For Their Future With Value Stream Mapping

Super Thin Saws (STS), located in Waterbury, VT, began as Schultz Tool Sharpening in 1976. In the 1980’s, they were largely assisted by California Cedar Products Company, who had developed the special design STS uses today; this was accomplished in partnership with the Mechanical Engineering Dept. at Berkeley and California Saw & Knife Works.

Gordon’s Window Decor – Making Their Future Bright By Embracing 5S As Standard Work

A Vermont-grown business, Gordon’s Window Decor (GWD) began operations in 1986 and has grown steadily, currently employing 26 full time workers. Based in Williston, Vermont, this woman-owned family business designs, manufactures and installs shades and comprehensive window treatments for businesses, schools, and homeowners worldwide.

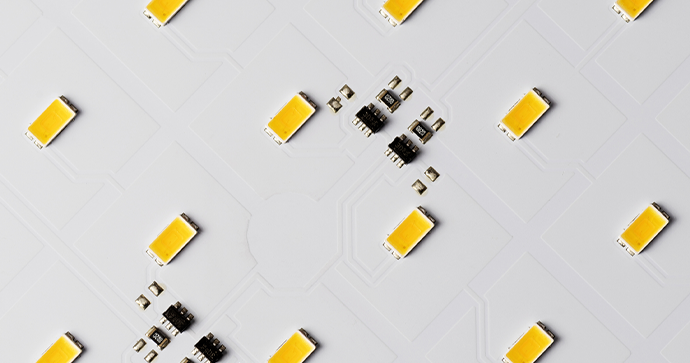

Advanced Illumination Revisits Strategic Planning, Leading To Improved Sales Efforts

Advanced Illumination (Ai) is an industrial lighting company, primarily serving the Machine Vision Industry. Founded in the Boston area in 1993, Ai was the world’s first LED lighting company. A developer and manufacturer of structured lighting and control electronics, Ai supports a wide variety of manufacturing activities around the globe.

Bee’s Wrap – Because Good Food Deserves Good Care

What do you get when you infuse organic cotton with beeswax, organic jojoba oil and tree resin? Bee’s Wrap, what else?! Seeking a way to eliminate plastics in her kitchen in favor of a healthier, more sustainable way to store her family’s food, Vermonter Sarah Kaeck, created a washable, reusable and compostable alternative to plastic.

Supervisory Leadership Development: Growing Supervisors & Leaders for a Lean Environment

Most supervisors are promoted from within, but too often without having any company-provided structured training to help these individuals succeed in their new leadership roles. When Mike Rainville, President, Owner and Founder of Maple Landmark Woodcraft decided he wanted to develop the leadership capabilities of his team of supervisors to become “Lean Leaders”.

LEDdynamics Improves Production Flow with Value Stream Mapping Project

LEDdynamics, a custom engineering company located in Randolph, VT, specializes in the design and integration of LED technology for end-user and OEM applications. Their breakthrough EverLED-TR fluorescent tube replacement has earned Popular Science’s “Best of What’s New” and EC&M’s “Product of the Year” awards.