VMEC Services

At VMEC, we provide a wide variety of services that help give you a competitive advantage. VMEC is the trusted resource for Vermont manufacturers when it comes to developing or enhancing your systems, processes, technologies and people. You know your business goals and challenges; we know the solutions that will elevate your success and growth opportunities for the future.

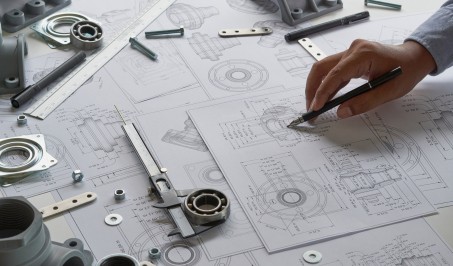

Advanced Manufacturing & Automation

We take a complete assessment of your people, process and operation and help you assess where to apply tools that will best strengthen your business.

Operational Excellence

VMEC will guide your journey of continuous improvement and promote a culture where employees at all levels are empowered. With the right tools in place, your business will become more flexible, efficient, and competitive.

People Development

We help companies engage, train, and mentor their existing team members, as well as attract and onboard new ones. We have the experience, know-how and network to strengthen your most valuable asset: your people!

Quality & Compliance

Partner with us to improve operations, build stronger relationships with customers and achieve long-term success through a commitment to quality and continuous improvement.

Innovation & Growth

We provide collaborative sales and marketing programs that address manufacturing specific challenges and accelerate business growth. When a company has an innovative culture, it’ll grow easily, the creative process will be simplified, and innovation is second nature.

Cybersecurity & Supply Chain

Both Cybersecurity and Supply Chain Management are about protecting the essential elements of your business, your reputation, and your relationships with your suppliers and customers. We provide resources and assistance to take action to protect and manage your business.