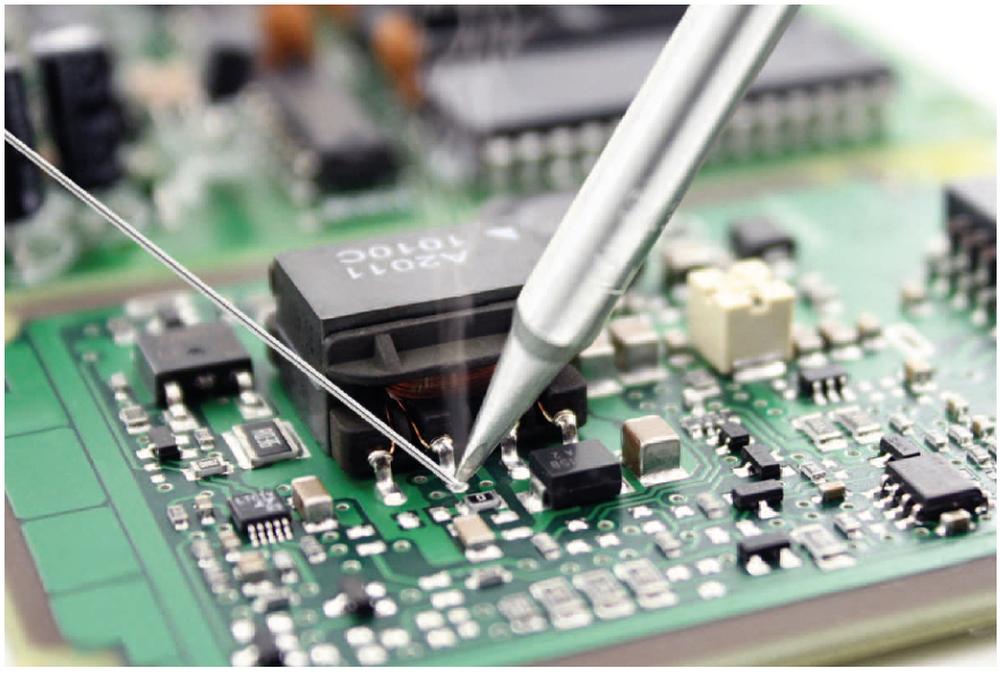

Hand Soldering Operator Certification focuses on teaching the foundation of soldering knowledge and the hands-on skills and techniques of how to solder. Technologies covered include: Wires and Terminals, Through-Hole, Through-Hole Rework, Surface Mount Technologies and Surface Mount Rework.

Using both lead and lead-free alloys, attendees will solder practice pieces, inspect them to submit for Instructor inspection and feedback before moving on to their final workmanship pieces to be graded for certification. Both the attendees and the instructor will inspect all pieces to ensure they meet Class 3 criteria.

Composed of five (5) modules, this program is a “hands-on” experience with approximately 75% of time experiencing the technology first-hand. This certification is provided by a professional training organization and includes all student manuals and soldering materials; recertification in two years is required. There will be a minimum of seven (7) persons and a maximum of ten (10) persons allowable for this week-long course. You must attend the full training week.

Daily agenda, which includes Continental Breakfast and lunch each day, is as follows:

Day 1

- Introduction to Soldering

- Specifications/Applicable Documents

- Terms and Definitions

- Tools and Material Selection and Maintenance

- Procedures in Making a Good Solder Joint

- Soldering Technology-Wires & Terminals

- Acceptability Criteria

- Wire Preparation

- Terminal Connections and Soldering

- Practical Session-Soldering Terminals

Day 2

- Lap Soldering

- Acceptability Criteria

- Splices – Wrap / Hook

- Heat Shrink Sleeving

- Practical Session-Lap Solder Joints

- Introduction to Through-Hole

- Specifications/Applicable Documents

- Electrostatic Discharge

- Through-Hole Terms and Definitions

- Tools and Material Selection and Maintenance

- Procedures in Making a Good Solder Joint

- Soldering Technology – Through-Hole

Day 3

- Practical Session-Through-Hole Practice Board

- Instructor/Student Review

- Acceptability Criteria

- Solder Rework Techniques-Through-Hole

- Through-Hole Component Removal Methods

- Practical Session-Through-Hole Rework-Practice Board

- Instructor/Student Review

- Practical Session-Through-Hole Test Board

- Instructor Inspection/Feedback

Day 4

- Introduction to Surface Mount

- Specifications/Applicable Documents

- Surface Mount Terms and Definitions

- Tools and Material Selection and Maintenance

- Procedures in Making a Good Solder Joint

- Soldering Technology – Surface Mount

- Practical Session-Surface Mount Practice Board

- Instructor/Student Review

Day 5

- Acceptability Criteria

- Solder Rework Techniques-Surface Mount

- Surface Mount Component Removal Methods

- Practical Session-Surface Mount Rework-Practice Board

- Instructor/Student Review

- Practical Session-Surface Mount Test Board

- Instructor Inspection/Feedback

- Course Summary/Review

NOTE: In order to ensure VMEC is offering the best business improvement programs to Vermont manufacturers and justify continued U.S. Dept. of Commerce funding for these services, participants may be asked to provide impact data and assessment through an impartial 3rd party survey firm 6 – 12 months after a VMEC-hosted public workshop.

Payment: VMEC will invoice you after the completion of the training.