What started as a Workforce Development Training Program for this leading global technology company that serves the medical and packaging industries ended up being so much more….

Husky Technologies had worked successfully with VMEC on multiple projects over the previous 20+ years at their Milton, VT facility. Their programs included Lean Concepts, Value Stream Mapping, Technical Support, Quality, Innovation Engineering and Advanced Manufacturing. In spring 2022, Husky identified a strategic opportunity to enhance and formalize its workforce development approach—ensuring it would meet the company’s evolving operational needs and future growth. With three shifts, 200+ employees, and a combination of manual and automated production lines, the team sought to strengthen a culture of continuous learning already deeply embedded in its operations. Building on a trusted 20+ year partnership, Husky re-engaged VMEC to support the design and implementation of a scalable, high-impact training strategy aligned with both business goals and employee development.

Planning sessions with Global Operations, Human Resources and on-site leaders across departments helped align and build the system they were seeking. Topics focused on real-time business needs as well as mentor, trainer and workforce program development that would help their business and customers succeed immediately and into the future.

Let’s Leverage What We Have and Develop a Plan Forward

Many foundational elements of a training program were already in place; these were assessed, adjusted, built onto and developed. Husky identified a strategic opportunity to formalize and scale its internal training framework. The scope of work for this nine-month project included:

- Frequent, on-site observation and coordination to assess and improve the current condition as it related to the vision

- Development and communication of the vision with global company leadership, articulating the desired outcomes and allowing for the workers, supervisors and local management to define and execute the path to deliver that vision

- Introduction and utilization of intentional learning cycles to break down the challenge into focused, actionable steps

By eliminating obstacles and illuminating more clearly the path ahead, VMEC engaged Husky leaders in attaining preset milestones leading to clear communication with stakeholders. During the implementation, a variety of proven continuous improvement and innovation practices were brought in when needed, modeled, taught and coached. These became the essential building blocks for a sustainable, flexible training and professional development program that can also support Registered Apprenticeships. Consistent and on-site VMEC engagement challenged and encouraged direct observation, collaboration and problem solving. Commitment and regular engagement of leaders throughout the project were essential.

We Have Momentum….Let’s Keep Moving Forward!

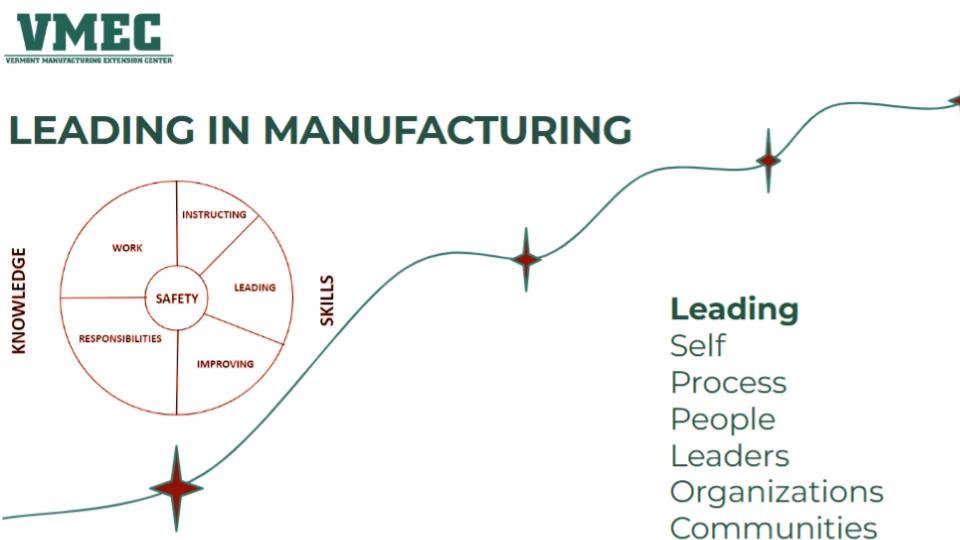

Building upon the success of the Training and Development Program, Husky continued to invest in the professional development of its leaders using VMEC’s Leading in Manufacturing Program, a tailored combination of Training Within Industry Job Relations (TWI JR), TWI Job Instruction (JI) and Root Cause Structured Problem Solving as well as other Lean Management and Change Leadership elements.

Leading in Manufacturing leverages TWI’s dynamic and proven approach to hands-on learning, practice and coaching. It develops leaders at all levels and provides critical skill development for frontline supervisors, team leaders and workers as the foundation for sustainable results in the workplace.

Carla Wuthrich, VMEC Director of Field Operations/ Professional Manufacturing & Business Growth Advisor as well as co-developer, instructor and advisor for the Leading in Manufacturing program shares: “I’m continually amazed at how a program like TWI, codified and shared over 85 years ago, can be subtly adjusted to remain wildly effective today as a foundation for effective training, people development, operational excellence, continuous improvement and other Lean critical elements that deliver quality products safely.”

Consistent, Competent and Confident Leaders in Manufacturing

While not unique to manufacturing, improving relationships with TWI JR and Change Leadership address the most challenging parts of a leader’s job – getting results through people, establishing and maintaining good working relationships and dealing with problems when they arise. Training and coaching leaders to use this proven, simple and repeatable process gives an organization an effective, consistent and coachable methodology. It increases the success and confidence of new and existing supervisors to reduce and address conflicts and create a work environment where individuals contribute to their fullest potential. The result is a competitive advantage, including the retention and attraction of talent.

Job Instruction training is crucial to establish stability in processes, ensuring consistency and reliability even as workers move on to other jobs or retire. JI trains employees to break down a given job and agree upon the “one best way” to do it, then train others to perform that “one best way” consistently and repeatedly. Process stability is generated across workers and lays the foundation for continuous improvement. As is the case with all TWI programs, JI is focused on developing the people who supervise workers and the workers themselves. Its emphasis is not only on building skills in the work, but also helps leaders make decisions about where and when to invest training resources.

Root Cause Structured Problem-Solving builds on the more generic and intuitive problem-solving process and is an integral part of continuous improvement. Intentional Plan, Do, Check, Act (PDCA) cycles with observation, data, collaboration, critical thinking and causal analysis, can build the team needed for the dynamic future ahead, while solving important problems now. In a focused, management-supported, data-driven way, Husky and many others get to the root of the problems and move the business and team forward. When VMEC is involved, workers from the CEO to front line personnel learn through real-world examples applicable to their organization.

What Did the End Result Produce?

As a leading Vermont manufacturing employer, Husky Technologies proved that partnering with VMEC led to the success of their most valuable investment – their people. Empowering their workforce through training and development, apprenticeship opportunities and recruitment and retention efforts drove success through all aspects of their business which will carry into their future for years to come.

“At Husky, we believe that empowering our people through structured training is essential to both operational excellence and employee engagement. Our collaboration with VMEC enables us to offer high-quality, scalable development programs that support individual growth and strengthen organizational capabilities.”

— Stacie Kordts, Vice President, Human Resources, Husky Technologies

“This program has created a real shift in how our teams approach both training and leadership. We’ve seen measurable improvements in communication, confidence, and operational consistency across shifts. It’s an investment that pays off daily.”

— Brian Gagne, Plant Manager, Husky Milton

“It’s been exciting to witness and be a part of the transformation to Husky’s Training & Development program in the past few years. With VMEC’s support, we have built upon Husky’s culture of teamwork and learning to inspire seasoned employees and upskill the next generation of skilled technicians.”

— Devon McGarry, Project Manager, Husky Milton