Kata is a Japanese term that can be translated to mean “a way of doing.” It can apply to any discipline that requires expertise in a pattern of behavior such as sports, music or martial arts. For businesses, it is important to understand that Kata can be used as a stand-alone skill or in conjunction with a structured problem-solving process such as lean manufacturing, A3 or any other continuous improvement approach. In fact, layering it on top of structured problem-solving processes can create better outcomes.

There are two types of Kata:

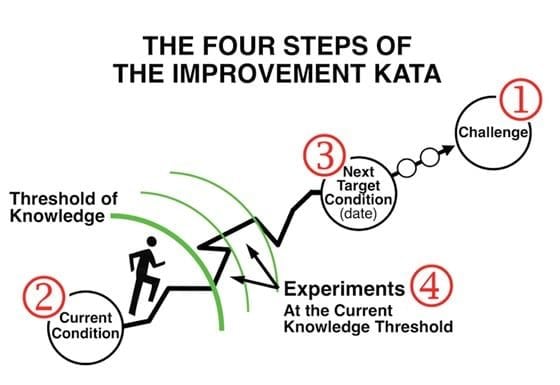

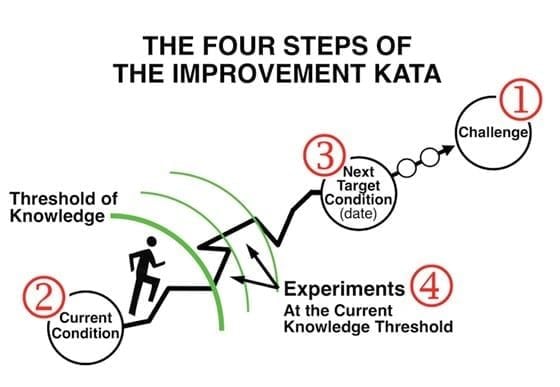

- Improvement Kata is a systematic way of thinking in order to improve, adapt and innovate. It requires organizations to take time to agree on a common goal or Challenge, understand their current condition—including problems and root causes—and work through grey areas using rapid Plan, Do, Check, Act (PDCA) cycles to reach their next target condition. As they move through the grey area, their Knowledge Threshold expands. While the Challenge for the Improvement Kata may be long-term, once the next target condition is defined, organizations can quickly see the obstacles preventing them from reaching this condition and begin experimenting to address them and capture learnings.

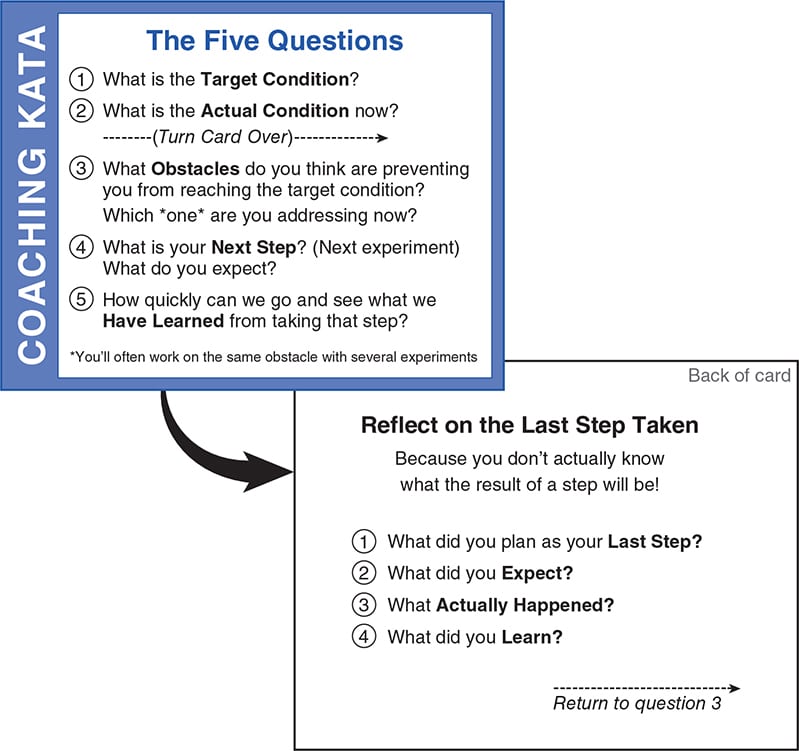

- Coaching Kata is a structured way of ensuring that Improvement Kata stays on-track. The coach reviews a series of questions with the learner such as:

- What is the target condition?

- What is the actual condition now?

- What did you plan as your last step?

- What did you expect?

- What actually happened?

- What did you learn? (The gap between what you expected and what actually happened is where the learning happens.)

The goal of Coaching Kata is to move learners through the grey zone and towards the target condition. Interestingly, by going through this process, learners naturally develop skills to become kata coaches for organizations.

Getting Started with Kata

Almost any problem in any sector can be solved with this approach. In fact, it is an ‘open source’ way of thinking that can be plugged into any existing organization or process. Currently, healthcare organizations and manufacturers are using it when they:

- Can’t agree on a goal

- Know where they want to be, but not how to get there

- Feel like they’re always starting over to solve the same problem

- Want to ease the burden of problem solving on leadership

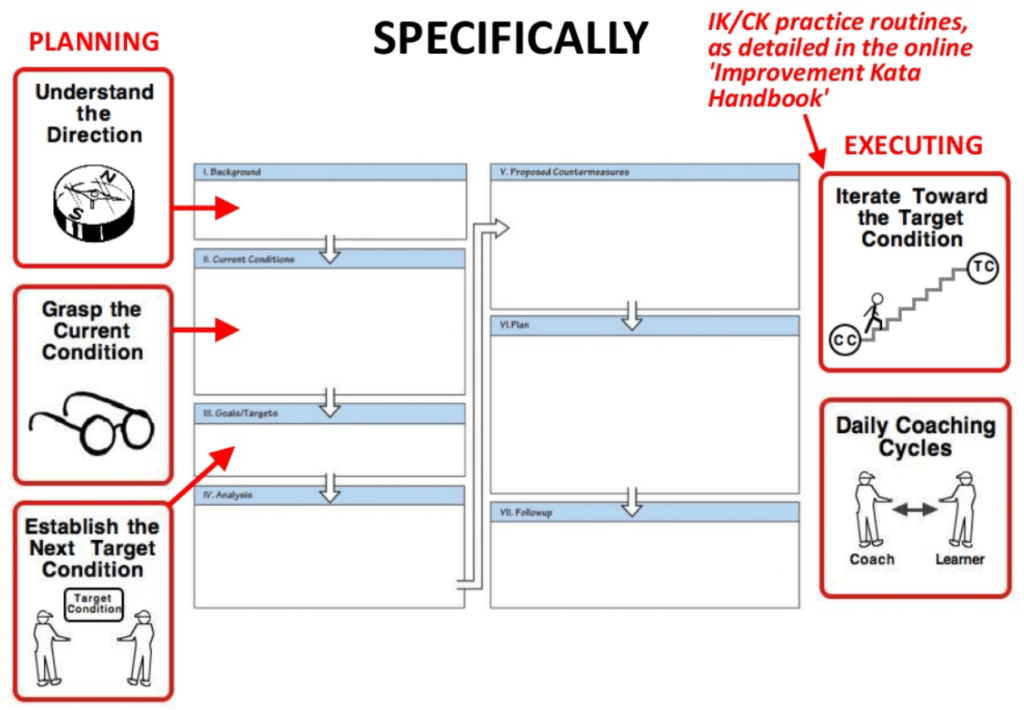

Kata allows organizations to align to a goal while removing politics and opinions from the equation. Before an Improvement Kata begins, team members must:

- Understand the Direction

- Grasp the Current Condition

- Establish the Next Target Condition(agree on what is NEEDED)

Once the above is defined, teams can move quickly by using Plan, Do, Check, Act (PDCA) cycles to test ideas and remove obstacles to the target condition.

Using Kata to Develop a Strong Improvement Culture and Capability

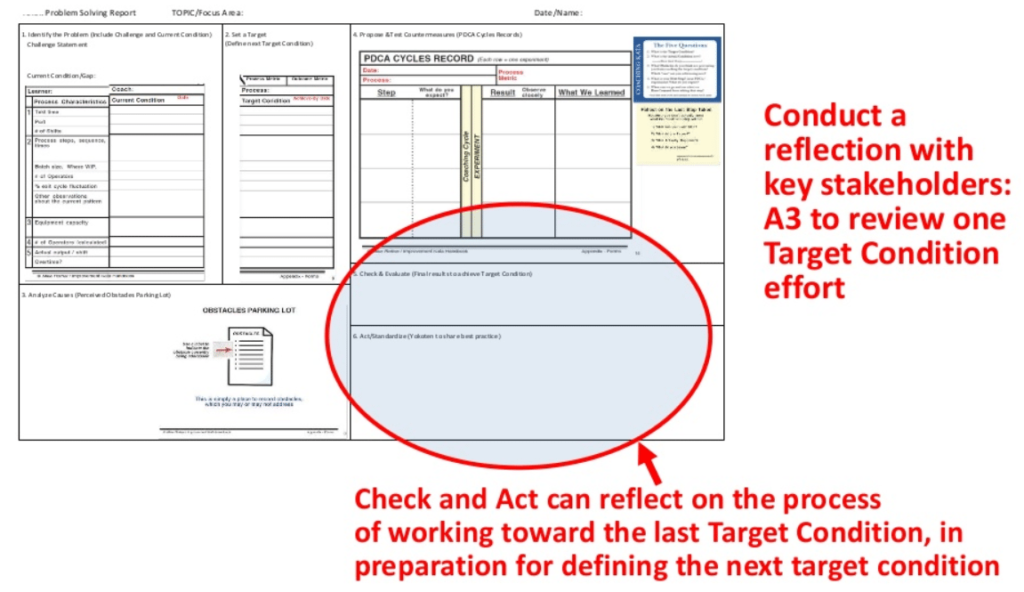

For organizations that use structured problem solving (such as A3) and have difficulty moving the program forward or sustaining it, it can be beneficial. Instead of throwing away A3 thinking, organizations can use Improvement Kata to provide faster, smaller cycles of learning that move them closer to their target position. For example, an organization with a safety concern might quickly find through experimentation that an inexpensive fix that hadn’t been considered will solve what was thought to be a very expensive problem.

This methodology also provides a more structured and scientific approach to lean manufacturing. Instead of hunting for waste and eliminating it randomly, it provides focus on the waste that NEEDS to be eliminated to reach customer aligned goals. This allows organizations to develop the skills that are required for sustaining lean over the long-term.

Kata helps organizations develop a strong improvement culture and capability.

Everyone is involved in at least one coached PDCA cycle at all times

| Everyone | (means everyone) |

| Is | (currently, NOT “oh, yeah, I’ve done one of those”) |

| Involved in | (does not necessarily mean leading. Providing perspective, data, etc as long as “the why”/alignment is effectively communicated to you, is being involved) |

| At least one | (one is acceptable, too many could be crippling) |

| Coached | (private a3 practice doesn’t count for this standard, albeit good to do. Need coach to continue skill development so that effectiveness, efficiency and aligned impact keep improving) |

| PDCA cycle | (visible process…could be A3 in pencil or electronic, using Kata or Gemba boards, back of a napkin, etc.) |

| At all times | (we are rewiring neurons here—it needs to be reinforced as “the way” to work, no matter the size of the hill you’re climbing) |

VMEC and Kata

For organizations looking to get started with it or reenergize their A3 or lean programs, VMEC has a long history with deep expertise helping organizations have meaningful conversations in order to improve, innovate and adapt.

With multi-layered expertise, VMEC can partner with organizations that are anywhere in their journey— from traditional starter Kata all the way through to applying Kata to structured problem-solving. And, VMEC also offers a unique 10-hour Improvement Kata and Coaching Kata program designed to help companies learn Kata concepts and patterns and develop a Kata culture in their organizations.

VMEC helps clients create excitement throughout the organization around improvement.

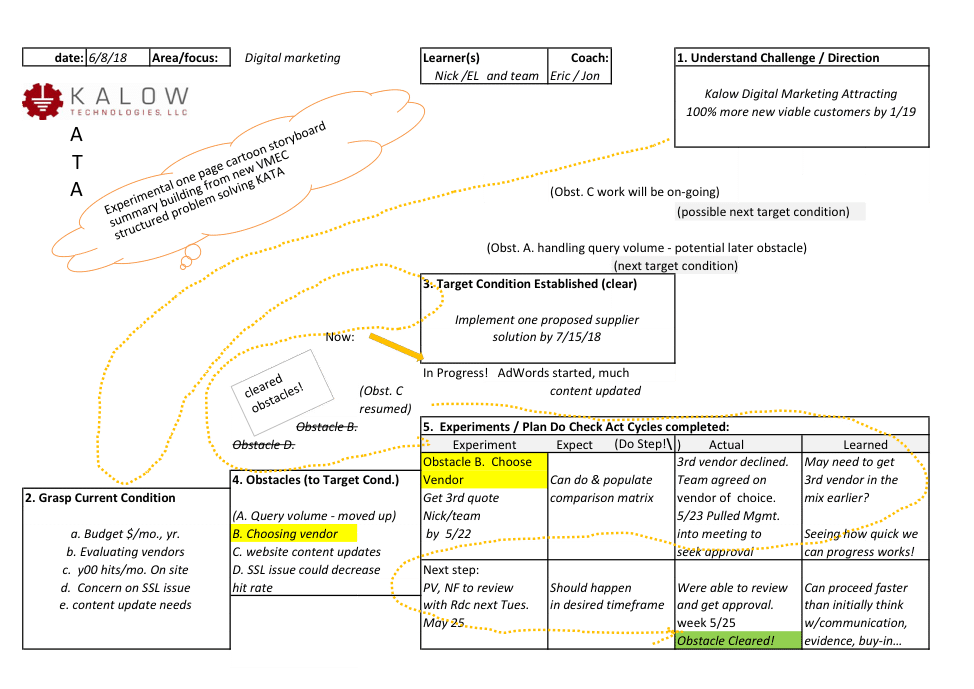

A Client Spotlight on Kata

Kalow Technologies is a contract manufacturer in North Clarendon, VT that specializes in electro-mechanical “turnkey” manufacturing services. For more than three decades, they have steadily built a reputation of rapid and professional responsiveness with a personal touch. As a result of this approach, they have grown alongside of their global customers.

However, with growth comes new employees and space constraints. In order to support this growth and ensure customer satisfaction, Kalow relied on their longstanding relationship with VMEC for assistance. Eric Lapp, Compliance Manager at Kalow shares “Kalow believes in the value of training and continuous improvement in order to ensure customer satisfaction.”

Kalow started their latest VMEC project in late 2017 with an introduction to structured problem-solving classroom training. “In the training, it became clear that Kata was the approach we needed,” said Lapp. The group brainstormed a number of various issues and started with eight Improvement Katas. Working in small groups of three to four people, the team tackled various targets throughout the company. These Katas looked at 100 different conditions and obstacles and employed 250 PDCA discrete steps in an eight-week time frame. Along the way, VMEC provided the Coaching Kata. The project returned rapid, and sometimes surprising results. One issue in receiving was resolved with a quick change to a form. Another Improvement Kata identified that an issue in purchasing was actually not where they thought it was at all.

Currently, Kalow is working on an Improvement Kata for sales and marketing with Lapp as the coach. The goal is to improve the number of new customers they attract via their digital marketing channels. Lapp has even created his own diagram for the team.

By using this approach, Lapp and team have rapidly identified the grey space. “Kata is such a good approach because it is scientific and concrete. It removes the ‘my opinion vs. your opinion’ conversations and gets everyone on the same page.”

To learn more about Kata, contact VMEC today.