Workforce Development Do’s and Dont’s | Five Common Mistakes

Three Factors for Success | Starting Your Workforce Development

Facing an often written about skills gap and employee retention woes, United States employers are faced with the daunting challenge of growing while having difficulty finding and retaining top talent.

Bloomberg stated in a recent article, “The skills gap in the U.S. is substantial. The National Federation of Independent Business found that as of first-quarter 2017, 45 percent of small businesses reported that they were unable to find qualified applicants to fill job openings.” This talent shortage combined with an ever-changing business climate has led employers to re-asses what workforce development means to their organization, and how it can be a competitive differentiator.

In fact, in March of this year Dominic Barton, Dennis Carey, and Ram Charan of McKinsey wrote “In our combined 90 years of advising CEOs and their boards, the three of us have never come across a moment like this, when virtually every CEO we work with is asking the same daunting set of questions: Are my company’s talent practices still relevant? How can we recruit, deploy, and develop people to deliver greater value to customers—and do so better than the competition? How can I be sure that I have the right approach to talent—and the right HR—to drive the changes we need to make?”

Organizations can answer these questions by using best practices for system improvement toward their workforce development goals.

Getting Started with Workforce Development—Do’s and Don’ts

The traditional view of workforce development is simply to educate employees in new skills. However, to truly get the most out of workforce development programs, companies must shift their mindset to understand that workforce development should be viewed as a workforce strategy that uses talent development as a component. The best workforce development programs differ from traditional education because the purpose of the program is to create an organization that can teach what is needed to be learned or applied at the time it is required in order to make improvements and move the company forward. In order for workforce development programs to have true impact:

- All levels of the organization need to be involved

- It must become part of a company culture of continuous learning

- It’s not simply about developing a training class, it’s about developing the ability to train and learn at the moment it is needed

- It is about improving business critical outcomes

Developing this mindset throughout the organization can show positive results for both employees—who feel like they’re making an impact—and overall business results.

Five Common Mistakes Organizations Make While Implementing Workforce Development Programs

Organizations sometimes decide to try workforce development and give up too soon. Some of the common mistakes they make are:

- Training (and learning) isn’t a capability. The ability to teach on a continuous basis is critical for the pace of change in today’s business climate. Organizations that think of training as a one-off project find that it has little impact on their overall growth.

- Setting it and forgetting it. Rapid changes in technology and business require organizations to adapt with new skills. Setting up a training program without a constant eye to what will be needed can negatively impact businesses.

- Only one group gets trained. Companies often train only one group. For example, in manufacturing the training focus tends to be towards the front line, without thinking about all of the other key players that need to adapt to the changing needs of the business.

- Training at the wrong time. When training isn’t aligned to what is needed by a person, a group or the company at that time, organizations will find that their dollars are being wasted.

- They think it’s optional and an expense. Organizations that believe workforce development is optional or view it as an expense are taking a short-term view. In the long-run, workforce development is an investment in growth—as long as learning is tied to overall strategy and the training is needed and used.

Organizations that think of workforce development as a one-off project find that it has little impact on their overall growth.

Three Factors for Workforce Development Success

While it can feel overwhelming to implement a learning program that never really ends, there are some core concepts that organizations can use in order to make workforce development effective and sustainable.

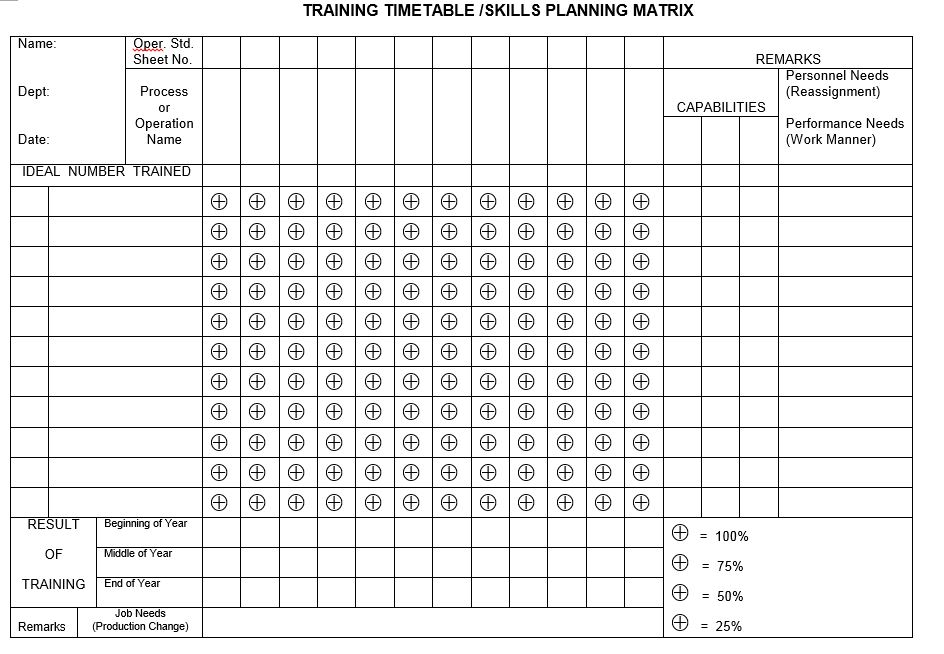

- Align workforce development to your business goals. Organizations that have a roadmap that defines who needs to get trained and when find workforce development less overwhelming. The below training timetable / skills planning matrix is an example of knowing who to train at a glance.

- Have a company-wide method for how training is done. Organizations must ensure that the entire organization knows how people get trained and that there is a common way to train. Creating a training framework saves time and money.

- Leaders understand their role as coaches. As workforce development is a culture that spans the entire organization, having leadership understand their role as a coach is key.

Figure 1. Build a training timetable like this one, based on Training Within Industry – Job Instructions (TWI-JI).

Note the Plan Do Check Act (PDCA) thinking as it relates to Training: a) Who needs to be trained b) on what c) by when d) data-based reflection and e) adjustments

The Benefits of Adopting Workforce Development

Developing the entire company’s capability to learn, coach and think critically allows everyone in the organization to be looking for ways to improve. This has a significant impact on growth.

Any organization or institution looking to attract and retain employees, increase customer value, reduce mistakes, bring new products to market, improve on-time delivery and product quality and increase profitability can use workforce development as a competitive advantage.

The trick is knowing what to train and when. That’s where VMEC can help.

Figure 2. Transformation Roadmap

Engaging with VMEC for Workforce Development

While other organizations want to train individuals, VMEC looks to expand its impact by helping companies improve their system for improvement and workforce development, leading to an organization that pulls for learning.

VMEC can customize curriculum with resources from around and outside the state to meet employee and organizational needs. This often takes the form of a combination of group learning and individual coaching to close the knowledge and skill gaps.

Organizations can avoid common workforce development program mistakes by leveraging VMEC’s expertise, experience with systems and longstanding relationships and insight.

VMEC helps organizations understand when to train, how often to boost training and how to add new skills that stick. With VMEC’s guidance, organizations can be confident that their workforce development programs are truly providing a good return on their investment.

And, the rewards can be immediate as well as long-term. Participants in a workshop often apply those concepts while in the class or soon after returning to the office. Whether starting small with a pilot project or looking to ”ROCK THE BOAT”, DIG DEEP or GO WIDE, VMEC can assist companies in developing a system and process to identify training and education that matches employee needs and organizational goals.

VMEC’s workforce development mission is to empower and strengthen Vermont Manufacturing by aligning people—new and incumbent workers at any career stage—to their organization’s strategy in order to drive industry and economic success.

A Spotlight on Workforce Development Success

Hayward Tyler MEGA 5S from Lake Champlain Productions.

Hayward Tyler, located in Colchester, VT is a 200+ year old company which designs, manufactures and services fluid-filled electric motors and pumps for high-pressure, high-temperature applications and environments across the global energy sector. Their US facility employs about 100 FTE with bases in the UK, China and India. Customers include GE Oil and Gas, KHNP, PSE&G and Dominion.

For several years, Hayward Tyler worked to lay the foundation for a culture of continuous improvement. However, recognizing the need for a more structured approach and assistance in building a continuous improvement culture, they partnered with VMEC for help with training, implementation and coaching throughout the organization. VMEC facilitated several 5S training and improvement projects and helped them to implement Value Stream Mapping.

VMEC proposed a waved approach to the training and project implementation to ensure that teams were able to both implement short term improvements and sustain the changes and continuous improvements over time. This approach focused on small, willing and intact work teams over a period of 3-4 months each.

The approach blended:

- Classroom style and simulation training

- Structured pilot projects in the factory and front-office operations to accelerate change within the zone of control—the value stream—of the teams

- Leadership and team coaching to support project implementation (this included support of internal book clubs to leverage learning)

- Tactical support where required in areas such as IT / ERP, QMS, and Metrics & Reporting.

As an outcome of these programs, Hayward Tyler has seen a 72% decrease in product lead time, a 100% increase in on-time product shipment and a 35% increase in the number of units built per year.

“VMEC has been instrumental in our success. We have been able to use the concepts and training they’ve provided to get us all on the same page and working on the right things. They have been a real collaborative partner in helping us achieve our goals.”

– Tom Parent, Director, Human Resources and Information Technology

Boost your organization’s capability to learn and see how it can translate into real ROI. Contact us to learn how we can help your organization.